THE CHEMICAL INDUSTRY

The chemical industry provides a wide range of possibilities for the use of various products in heat recovery. That is why this industry is an important area of focus for ATHCO-Engineering A/S.

One of the world’s leading industries

The chemical industry is steadily growing worldwide and is today one of the world’s leading industries. Engineers around the world are daily working with heating and cooling processes facing the challenge to select the right equipment and how to optimize processes and energy consumption using heat recovery without occupying too much space, reduce cost and CO2 emissions.

We create a suitable solution for you

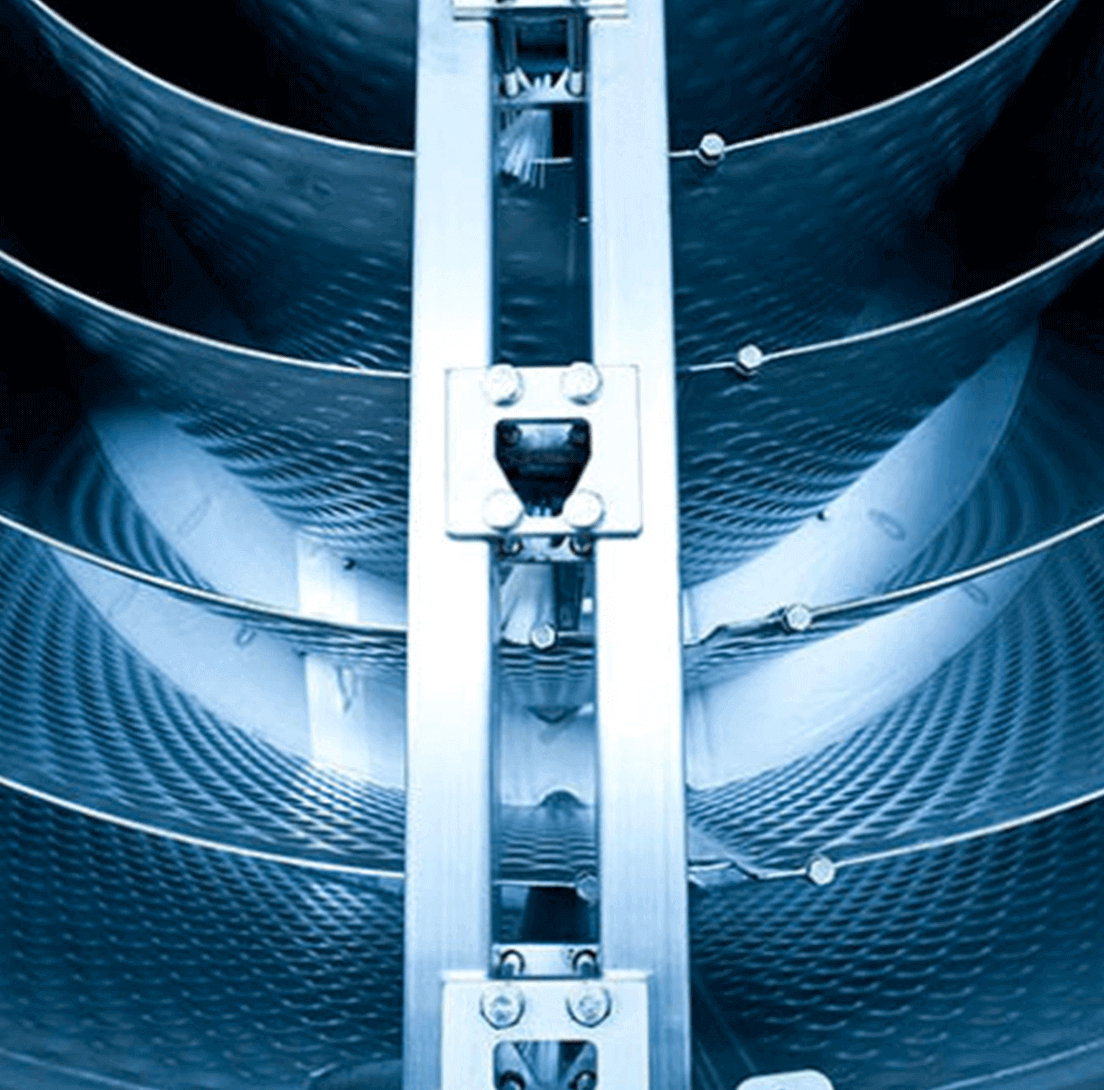

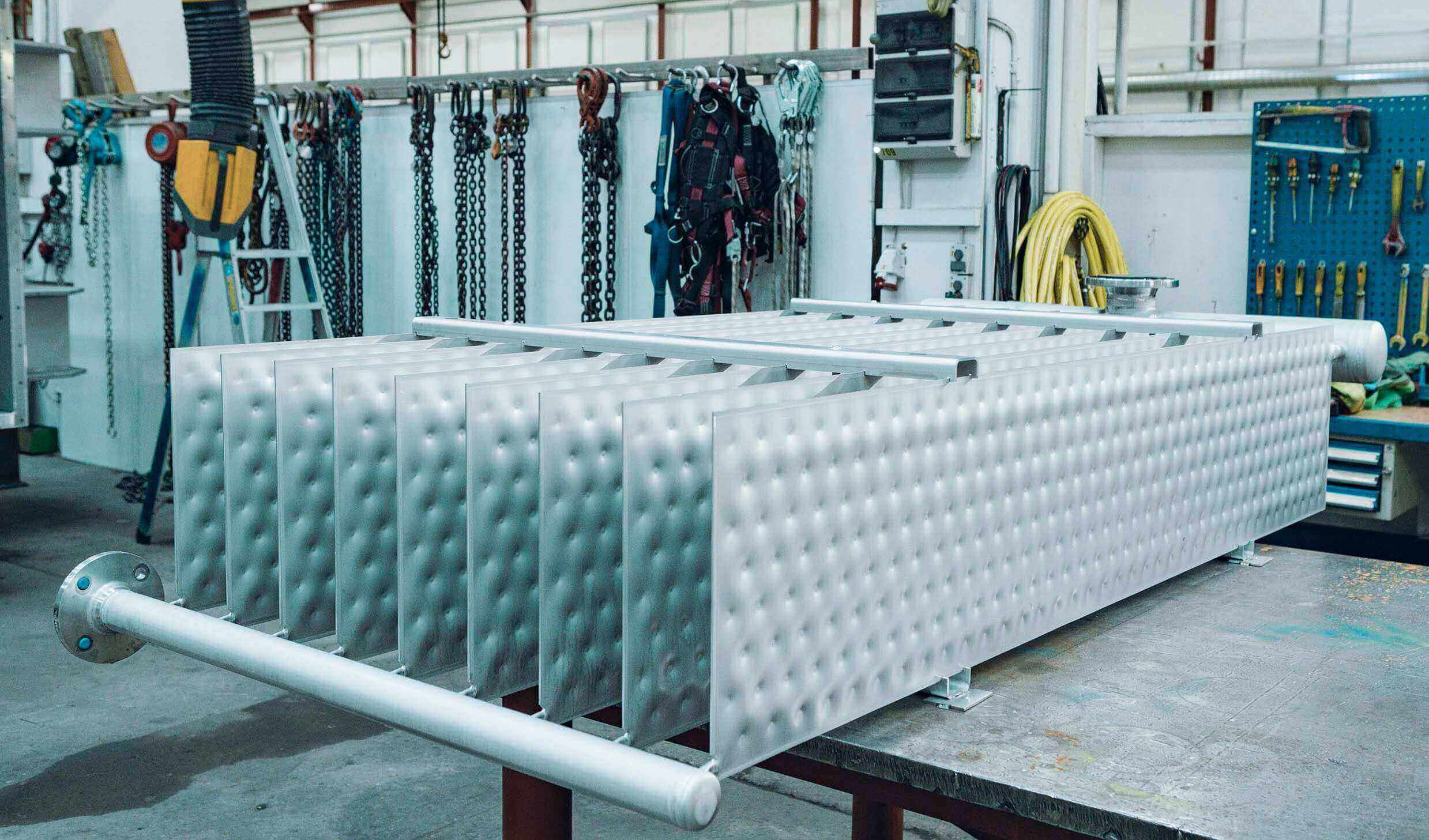

There are a great variety of different processes in this industry, where cooling or heating of fluid or gasses is a necessity. Thermoplates can be designed in all shapes and dimensions as fully welded constructions for both high pressure and temperatures opening new ways for the engineers to solve heat recovery problems and reduce cost.

In such situations ATHCO-Engineering A/S significant experience, when dealing with heat recovery in the chemical industry, will be an important factor in a collaboration, where we co-operate with our customers to creating a total solution suitable for them.