Heat Recovery case

Welcome to ATHCO-Engineering’s Heat Recovery Case Solutions. Our innovative approach helps you tap into previously wasted heat, transforming it into a valuable resource for energy efficiency and sustainability. Explore how our solutions can benefit your operations and reduce costs.

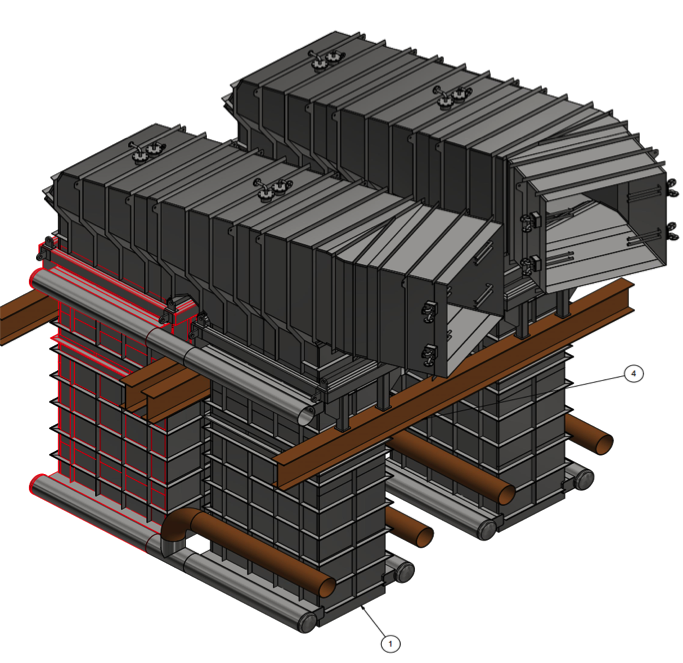

EON Norrkopping Händelöverket replacement

- Design, manufacturing and installation of Flue Gas Condensers including auxiliary equipment

- Scope: Engineering and supply of Two Thermoplate condensers, spraying system, quench and spray hood including piping valves and secondary steel etc..

- Application. Flue Gas Condensation Plant

- Customer: Eon Sweden

- Plant: Händelöverket, Norrköping

- Country: Sweden

- Size: 2 x 1840 m^2 Effect ~18 MW

The challenge

- Two condensers delivered by us twenty years ago were corroded and had to be replaced.

The solution

- The plant use heat recovery for district heating with a heat load of 9 MW/condenser

- The units were delivered and installed in time and the result has been to the full satisfaction of the customer.

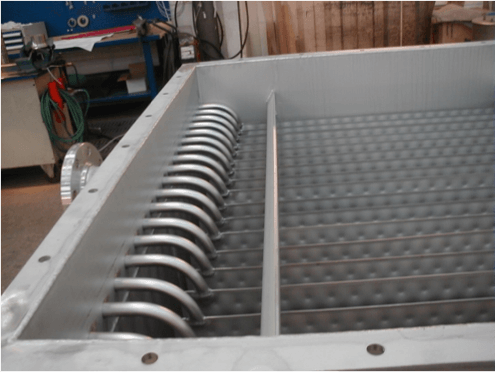

Heat Recovery From Spray Drying

Application: Heat Recovery

Country: Italy

Segment: Personal Health Care

Media shell side: Exhaust Gas

Media lamella side: Water

Design pressure: 1/6 bar

Design temperature: 130 ℃

Material plate bundle: EN 1.4404

Material housing: EN 1.4301

The challenge:

Reduce energy consumption for spray drying, with a cleanable design on exhaust gas side.

The solution:

Proces Therm with cip nozzles

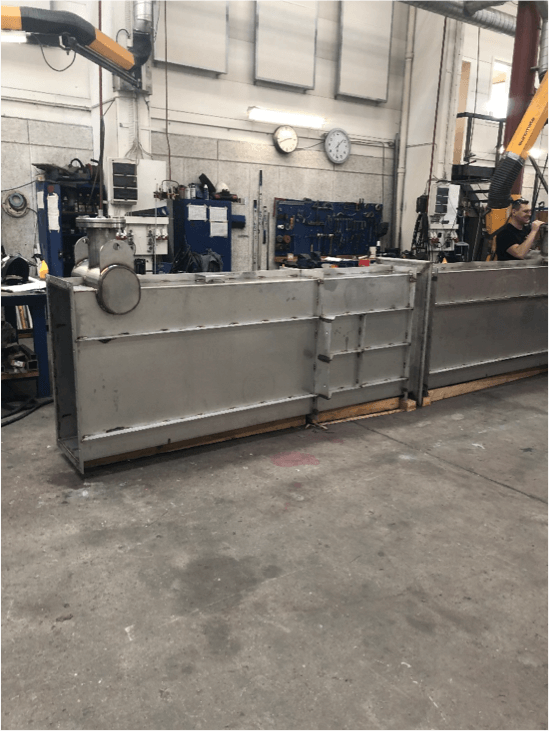

Heat Recovery From Food Production

Application: Heat Recovery

Country: Denmark

Segment: Food

Media shell side: Exhaust Gas

Media lamella side: Water

Design pressure: 1/10 bar

Design temperature: 100 ℃

Material plate bundle: EN 1.4404

Material housing: EN 1.4301

The challenge:

Heat recovery for district heat network with a free flow design on exhaust gas side Low pressure drop on gas side in order not to interfere with production high recovery, high condensation rate

The solution:

A long, thin flue gas condenser. Output like 400 households yearly district heating consumption

HEAT RECOVERY FROM SPRAY DRYING

Replacing an old heat exchanger within confident space and limited acces

Application: Heat recovery exhaust gas

Country: Germany

Cusstomer: MTW Neumunster

Segment: Food

Media shell side: Exhaust Gas

Media lamella side: Water

Design pressure: 1/8 bar

Design temperature: 90 ℃

Material thermoplates: EN1.4404

Material housing: EN 1.4301

The challenge:

Replace a heat exchanger within confident space and limited access to the old installation.

Not to interfere with production and pollute the project with dust etc.

Hygienic area not to be compromised

The solution:

PROCES THERM WITH CIP NOZZLES

Built on site by ATHCO-Engineering A/S welders within a shielded workspace.

Materials lifted on site thru a window in the top of the building 50 meters in the air

Contact ATHCO-Engineering A/S

regarding this solution