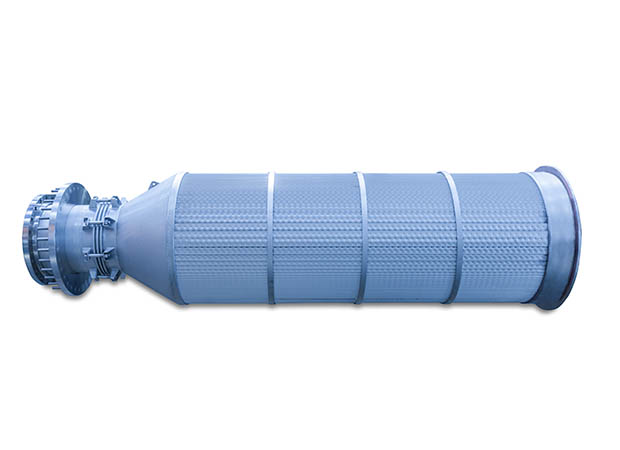

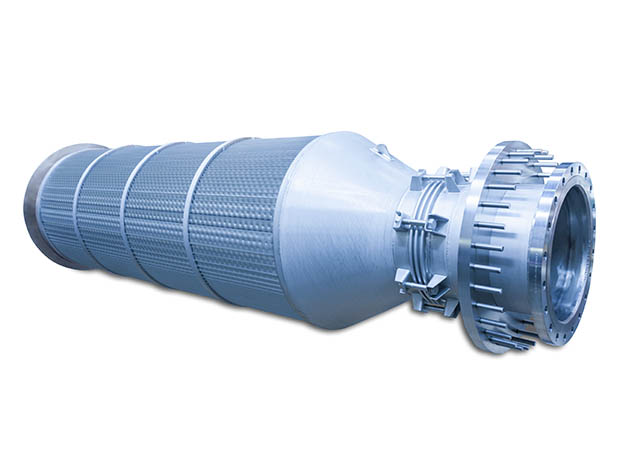

Thermoplate Heat Exchanger

TP-HEX is a compact, round heat exchanger where, typically, the hot medium runs between the plates, and the cold medium inside the plates in a counter-current flow.

No baffles are applied so the available pressure drop on the hot side can be utilized by having a small gap and relatively large velocities between the plates. Together with highly turbulent flow inside the plates, this results in an excellent heat transfer.

Another advantage of the small space between the plates is the compact design with a large heat transfer area per m³. This makes it a great solution for existing plants where space can be limited.

Design

Thermoplate Heat Exchanger can be manufactured in a large range of stainless steel qualities (304, 316, SAF 2205, 904L etc). With a few adjustments, ATHCO-Engineering A/S makes sure that the TP-HEX becomes the perfect match for a wide range of applications such as condensation, evaporation, as well as sensible heat transfer. The TP-HEX can be operated vertically or horizontally.

Low maintenance costs

The thermoplates in TP-HEX have a self- cleaning effect due to their smooth surface. This reduces the fouling tendency to an absolute minimum, meaning there is also less of a need for maintenance.

TP-HEX is constructed with easy access for cleaning. The thermoplate bank can be dismounted very easily and cleaned with a pressure washer, for example.

The TP-HEX has no seals because it is built as a fully-welded structure. This means many of the maintenance costs connected with seals are avoided. The TP-HEX can also have higher design pressures than seal-based heat exchangers.

PRODUCT ADVANTAGES

- Low maintenance costs due to self-cleaning effect and construction without seals

- Compact design saves space and installation costs

- Up to 3 times smaller than a tube heat exchanger

- Efficient heat transfer because of large contact surfaces

- Low fouling tendency because of optimum turbulence

Contact ATHCO-Engineering A/S

regarding this solution