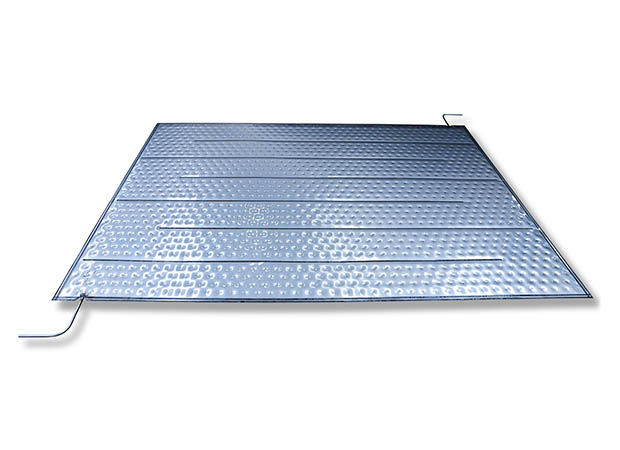

Pillow plate thermoplate

heat exchangers

Pillow plate at the heart of our heat exchanger technology is the thermoplate also called pillow plate or embossed plate due to the shape of plates after expansion.

What is a Thermoplate?

A pillow plate is a fully welded heat exchange plate. The plate consists of two plates that are spot-welded together. The plates are sealed with a welded seam along the contours of the plates. The plate is finally expanded until the desired expansion height is achieved. The expansion height is the maximum space between the two plates.

Pillow plates(thermoplates) and Dimple plates are similar products both made from stainless, but they also have distinct differences. The Dimple plate are a preformed plate to be attached to the final form afterwards. The pillow plates are included in the design before the final form. The dimple plates can be used for existing equipment, but only allows for a pressure below 6 bar. The pillow plate design allows for higher pressure.

A fully welded heat exchange plate

Material selection is of course essential when selecting the right design for a heat exchange duty. But another and sometimes more important factor is the welding of the thermoplates. A thermoplate can have several hundred spot welds – each a potential risk for corrosion or fouling if not handle with care. ATHCO-Engineering A/S use resistance welding to produce the spot pattern and the seam welding for the thermoplates.

What are Thermoplates used for?

In short heat exchangers, due to the flexible nature of the Thermoplates, they are applied in several different heat exchanger applications:

Condensation

– Steam

– Partial

– VOC

– Vacuum

Feed/Effulent

Gas/Liquid

Gas/gas

Liquid/Liquid

Fouling applications

Pyrolysis, Syngas

Chilled water

Ice production

Cooling / Heating jackets

No add material to weld

Limited pollution of the metal sheets.

The corrosion and strength of the materials are maintained.

No visible welding seems

Hence no nucleated spots for fouling, corrosion and freezing.

No crevice – highly susceptible for corrosion.

Only a low heat input at the welding spot

The strength and corrosion resistance of the heat-affected zone is nearly that of the parent material.

No space behind the welding

No risk of corrosion in between the weld metal sheets.

Product advantages

- Very easy to clean (high sanitary standard).

- Efficient heat transfer because of large surface area to volume ratio.

- Compact design and simple installation.

- Good thermal operation efficiency due to high heat transfer coefficients.

- Each heat exchanger is individually designed for the heat load, flow rate and pressure drop limitations of the specific application.

- Self-cleaning effect due to the smooth surface of the thermoplates.

- Fouling tendency is reduced to an absolute minimum, and that also applies to the need for maintenance.

- Energy-saving and greener solutions.

About ATHCO-Engineering A/S

ATHCO-Engineering A/S is a Danish company founded in 1947

Today we are a leading specialist in advanced heat transfer technology and recovery. Our core business is to design and manufacture tailor-made equipment for the process industry. Our mission is to optimise our customers’ process, and we provide innovative cost-reducing solutions customized for every single project.